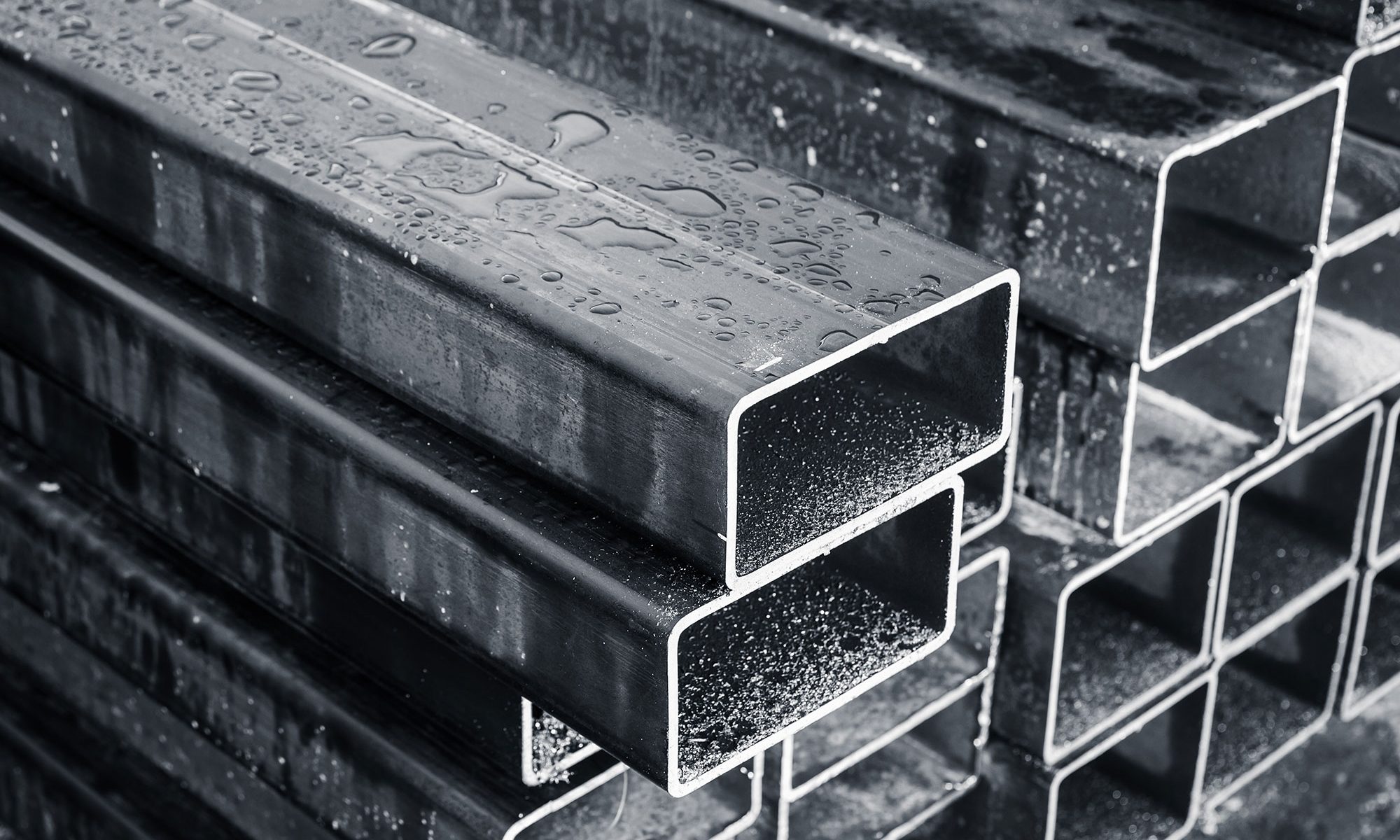

Rectangular ERW tube is one of the many products we work with. We do so as it’s a versatile and widely employed product suitable for many industries. Examples include engineering, manufacturing, and construction. When it comes to picking the right length and size for these tubes, there is a lot to consider. Our aim here is to offer you a comprehensive guide on choosing the most suitable dimensions for your projects.

Understanding dimensions

Firstly, you need to ensure you understand the rectangular tube dimensions. They consist of four sides that have rectangle cross sections. The tube’s dimensions are normally specified by wall thickness (T), width (W), and height (H). Then, the length can vary by the project demands.

Firstly, you need to ensure you understand the rectangular tube dimensions. They consist of four sides that have rectangle cross sections. The tube’s dimensions are normally specified by wall thickness (T), width (W), and height (H). Then, the length can vary by the project demands.

You need to inspect load requirements as well. In fact, it is the first step in choosing the right length and size for your rectangular tube. Analyse the load’s magnitude and type. This can include static loads or dynamic ones. Understanding these requirements will help you dictate the right rigidity and strength.

Structural considerations

These play an integral part in figuring out the right size for your tubes. Factors like the desired safety and anticipated deflection limits need taking into account. It is also the same for the span between supports. Discussing these matters with experts gives you valuable insights. You will then be able to select the right dimensions. If you need ERW tube, give us a call.

Maximum strength

Understanding the total allowable stress for your tubing is critical. We are talking about the total the material withstands before it fails or deforms. The max is normally supplied by material codes or specifications. By considering this stress, you can decide on the suitable wall thickness. Therefore, you can guarantee structural integrity and safety.

Buckling

This consideration is on the list too. Buckling refers to a crucial failure mode for slender members like tubes. It happens when the compression forces tubing to exceed its capacity. The tube ends up collapsing. To stop buckling, your rectangular tube’s slenderness ratio (L/R) needs to remain in acceptable limits. You need to get the correct ratio of the length (L) to the radius of gyration (R). Consult engineering guidelines or codes. Doing so will help you with the total allowable slenderness for loading conditions.

Deflection and fitness requirements

Both of these factors are also important. Stiffness and fitness needs for applications influence the length and size of rectangular ERW tube. Excessive deflection can have an impact on the functionality and stability of a structure. As for insufficient stiffness, it can cause bending or sagging under loads. Knowing the acceptable deflection limits and then choosing the right dimensions will guarantee performance.

Manufacturing considerations

These should be on your mind as well. When picking the length and size of tubes, think of the manufacturing process limits. The availability of regular lengths and sizes might influence your options. Moreover, the feasibility and cost of manufacturing custom sizes need evaluation.

Aesthetic and design factors

It is true that the main focus on picking the right rectangular tubes is structural stability. However, design and aesthetic factors might play a part too. The visual appeal, finish, and appearance can be essential for decorative and architectural projects. These choices can affect things like dimensions and surface treatment.

We have many types of ERW tube available

At Union Steel Tubes, we supply a large variety of tube products, including rectangular ones. This particular shape is ideal for structural applications. You can find them inside buildings as well as in part of bridges to give some examples.

So, if you need quality ERW tube for any project, be sure to let us know. We can deliver it for you efficiently and for great prices.