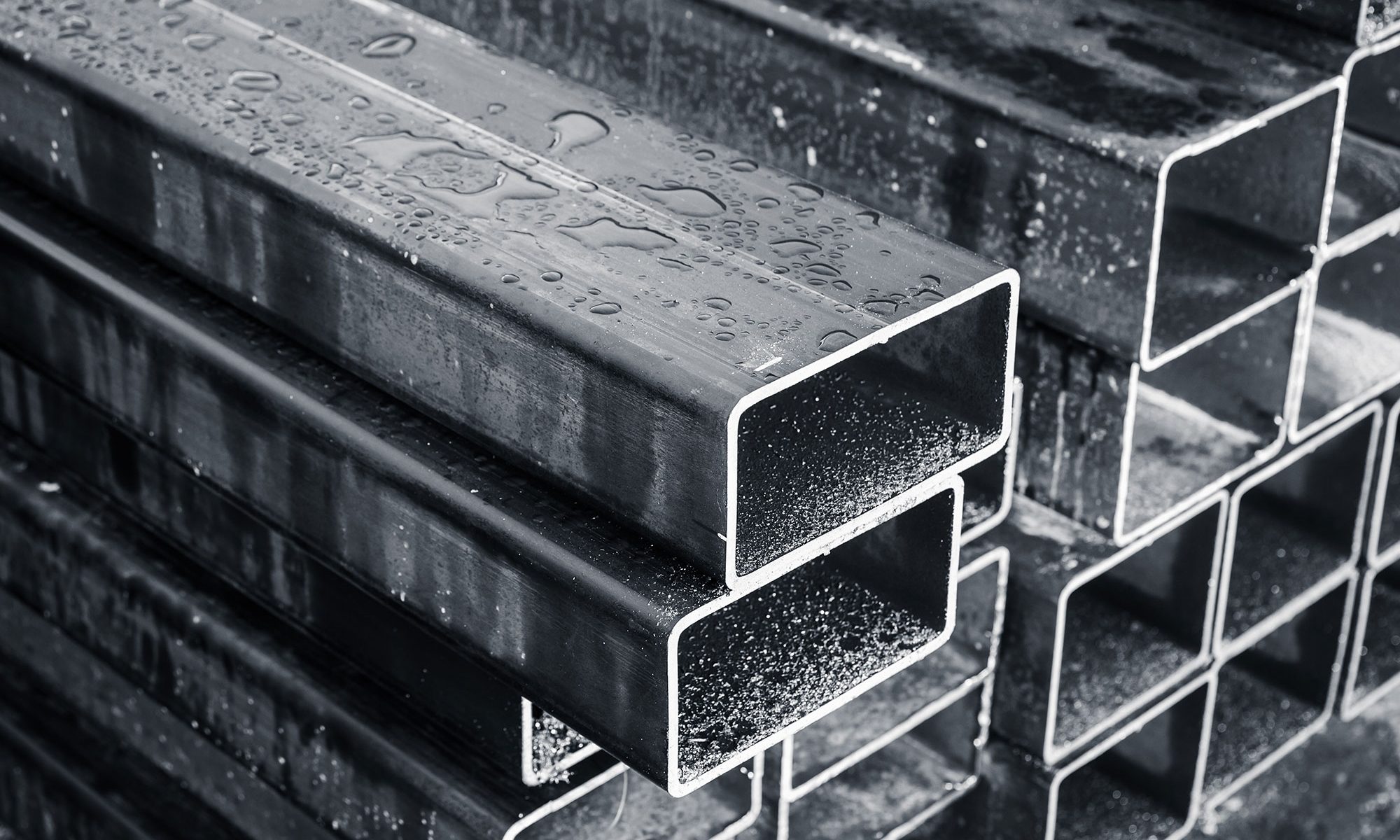

With manufacturing and construction projects, selecting the right materials is critical. You will need them to obtain aesthetic appeal, cost effectiveness, and structural integrity. A versatile solution that has gained major popularity over the years is rectangular tubing. We want to discuss the myriad of benefits it has to offer. Then, if you want to order from the top ERW steel tube supplier in the West Midlands, you can come to us. Continue reading “Use the advantageous rectangle tubes for your projects”

How does the heat treatment of metal work?

Heat treatment is a process for various metals and alloys, including objects like ERW tubes. You heat them to a particular temperature, keep them at that level for a certain time, and cool them at a controlled rate. The treatments change the mechanical and physical characteristics of metal, including ductility, toughness, and hardness. This is without modifying the composition or shape. Continue reading “How does the heat treatment of metal work?”

Steel storage racks are perfect for workplaces

Effective storage solutions are vital for businesses in every sector. They can be the difference between efficient operations and major issues. You can use many different systems here, including racks, shelving, and more. What you need to think about though is the materials they are made from and whether they will suit your needs. Steel tubing can be a fantastic choice because it is strong and durable, but still light and adaptable. We can help with this, offering the finest ERW steel tubes in the West Midlands for all kinds of needs. Continue reading “Steel storage racks are perfect for workplaces”

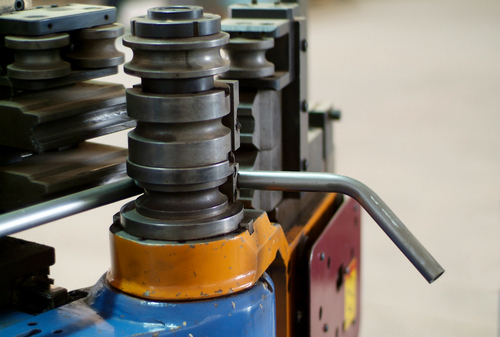

Essential things to consider when bending ERW tubes

There are lots of potential applications for ERW tubes. Expert processing services can facilitate many of them. For example, you could choose tube bending to create a curve, an angle, or even a ring or spiral. Further fabrication and assembly can then result in even more products. Continue reading “Essential things to consider when bending ERW tubes”

Choose steel over PVC

Buildings depend on their tubing to keep the structure functioning. The tubes are responsible for things like HVAC systems and plumbing. They can also be structural elements. When choosing between PVC and steel tube, there needs to be an understanding of the attributes of both materials. It’s true that each material has its own advantages. Yet, the features of steel have led to it becoming more suitable for projects. Let’s find out why, then you can come to us for ERW tube if you need it. Continue reading “Choose steel over PVC”

A quick look at ERW tubes vs SSAW tubes

Steel tubing is perfect for a number of needs, including pipelines, railings, furniture, and much more. However, there are many different types. Two of the most interesting are ERW tubes and SSAW tubes. We want to have a look at the two here with a comparison of how they are made and crucial differences. Continue reading “A quick look at ERW tubes vs SSAW tubes”