Businesses need to ensure they have the right infrastructure to maximise productivity, uptime, and profits. However, they may overlook a number of things that can have a massive impact. One thing in particular to think about is fluid handling characteristics. They can influence what type of tubing to choose, including steel ERW tubes. We want to have a closer look at why they are so important here.

Two crucial factors

The fluid handling characteristics determine two important things. Let’s examine them.

Efficiency

Firstly, they will decide efficiency. Systems will always be more efficient when they can effectively transfer high volumes of resources.

Firstly, they will decide efficiency. Systems will always be more efficient when they can effectively transfer high volumes of resources.

A pair of things will have an impact on the efficiency; the carrying capacity of the tube and friction loss rates. Generally, tubing with larger diameters has a higher capacity. However, you can’t simply choose massive tube. As size increases, so too does flow velocity and turbulence. Too much of either can damage the infrastructure.

The friction loss rate will also have an impact on efficiency. As resources flow through tubing, whether it is water, oil, gas, or anything else, there will be a loss because of how it flows along the inner surface. The rougher the inside of the tube is, the bigger the affect. So, if you want to maximise efficiency, choose a smooth interior that won’t inhibit the flow.

Maintenance

The fluid handling characteristics will also have a direct impact on maintenance, whether you choose steel ERW tubes or other materials. You will need to spend more time and money maintaining tubing when there is excessive flow velocity and turbulence. High friction loss rates also cause more wear within the tube.

The roughness of the inside of the tubing plays a major role here too. A rough surface can allow fluid and mineral deposits to build up. It can result in fouling and rapid degradation in these spots. In some cases it can cause pitting and corrosion. Ultimately, the tube could fail. So, it has a direct impact on the amount of maintenance you need to do. In the worst situations, it will lead to higher replacement costs.

Consider the C factor

The Hazen-Williams formula is one of the accepted ways to calculate friction head losses in tubing. The lower the Constant (C), the higher the friction. Therefore, typically you want to choose tube with a low C to maximise performance.

It is also important to look at how the C factor could change over the service life of the tube. For example, new steel or cast iron pipe should score between 130 and 140. However, after 4-12 years of service, the latter could be down to 120. It could get as low as 60-80 if there is pitting. Old steel pipe could fall to 125 after a few years of service.

Do you want to order ERW tubes?

What businesses need to keep in mind is they will get the best results when they choose quality tubing. It is definitely worth looking at the fluid handling characteristics. They can indicate what to expect in terms of performance and ongoing maintenance costs.

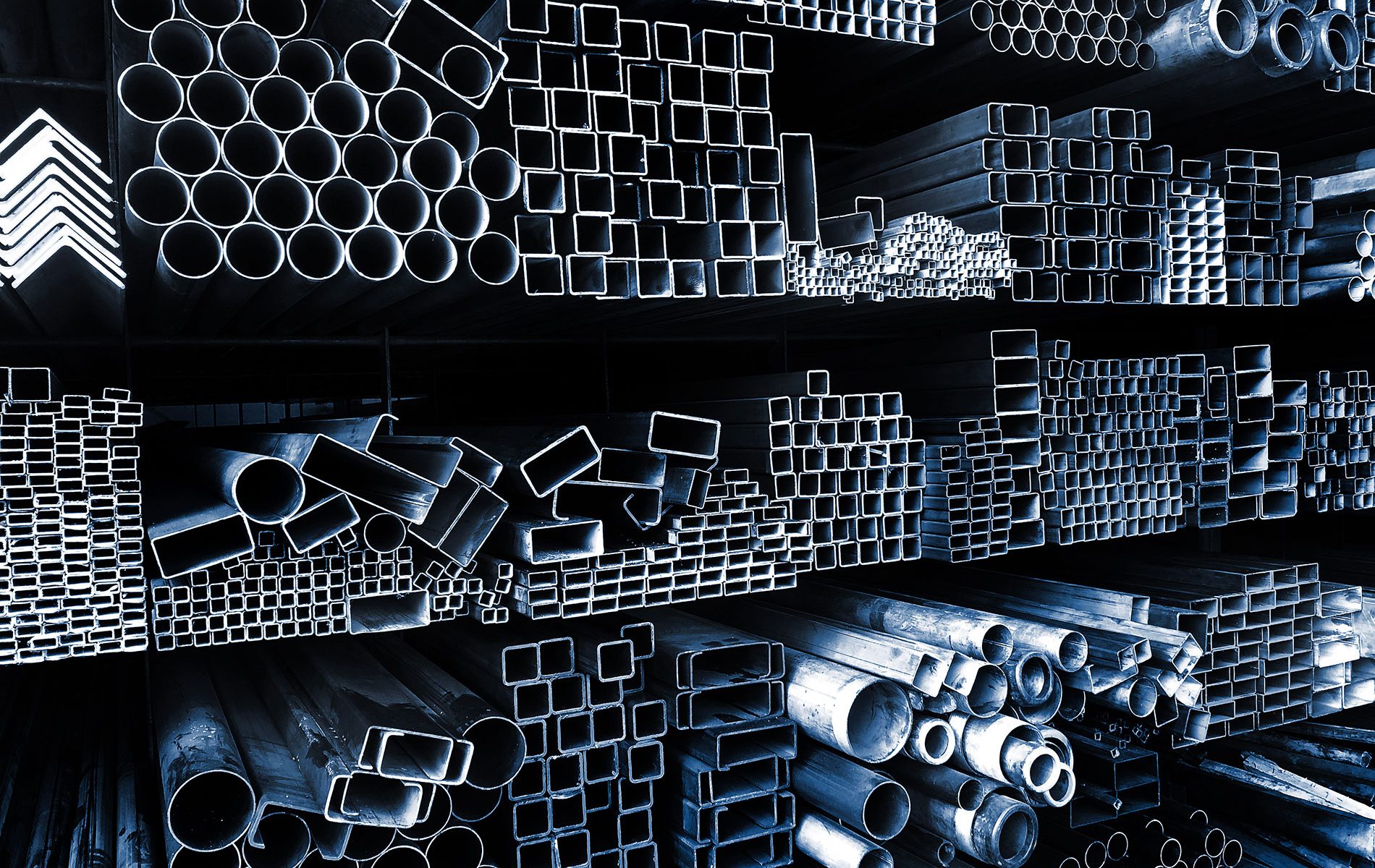

Union Steel Tubes is one of the most reliable suppliers in the UK. We can offer a massive selection of tubing, with an array of shapes, diameters, wall thicknesses, and finishes. We also cut to size in-house, ensuring we can supply lengths for almost any need.

So, if you need ERW tubes, please contact us. We can help you to select ones for any application, including industrial infrastructure.