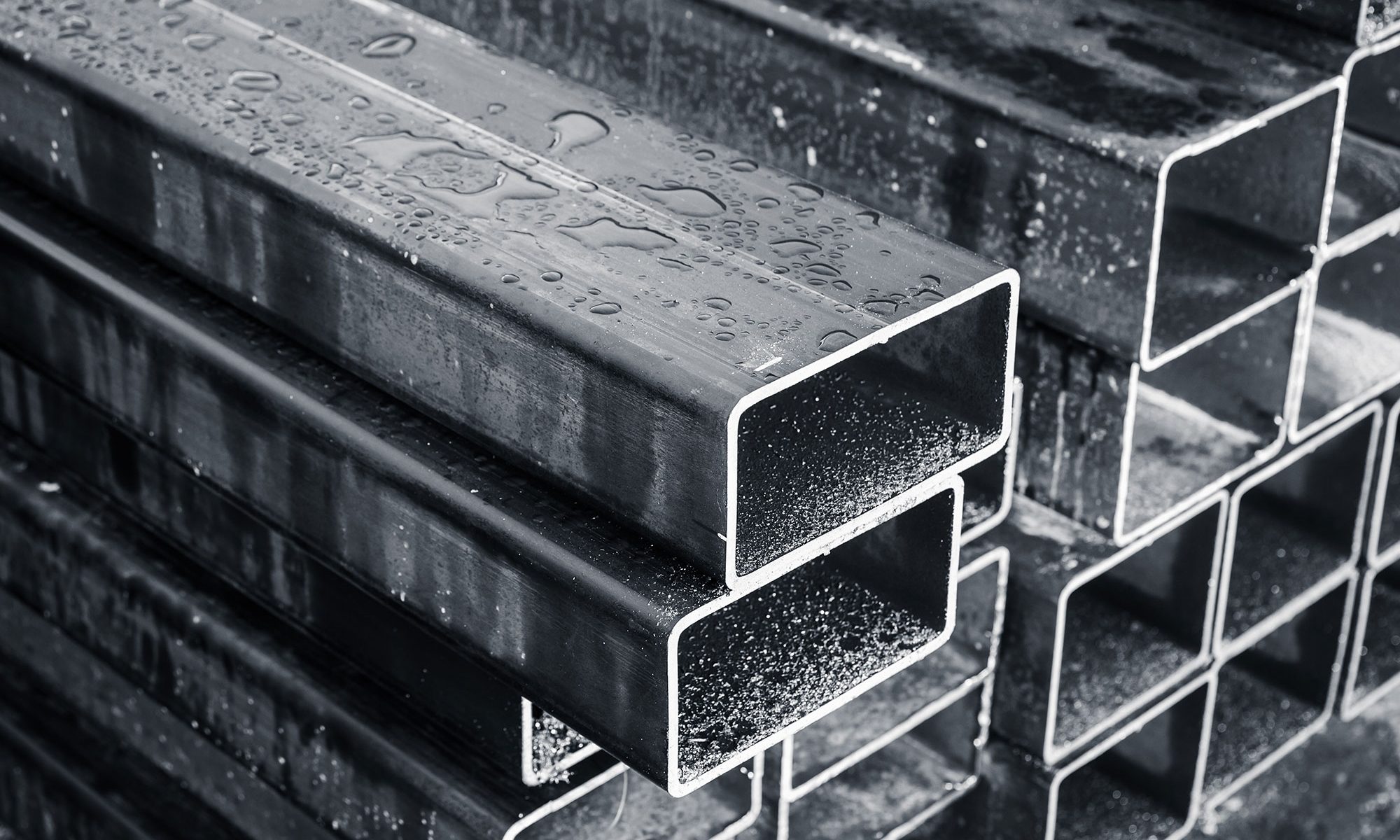

We are an establishment that aims to provide the most reliable metal tubing. These are quality tubes capable of serving applications in many different industries and settings. As the top ERW steel tube supplier in the West Midlands, we can help you get the right parts for any job. We can also deliver to you quickly.

We are an establishment that aims to provide the most reliable metal tubing. These are quality tubes capable of serving applications in many different industries and settings. As the top ERW steel tube supplier in the West Midlands, we can help you get the right parts for any job. We can also deliver to you quickly.

The performance of steel tubing depends on certain factors. These include the type of heat treatment and the effects of chemical elements when you include them in alloys. The latter in particular is important to understand so that they come with the right features. What we want to do is a deep dive on the effects certain elements have on steel. So, read on to learn more.

Chromium

Firstly, chromium has the ability to improve strength in steel tubing. Other characteristics it can enhance are wear resistance, corrosion resistance, and hardness. This is a vital alloy element of stainless steel. On the other side, chromium can decrease the material’s toughness and plasticity.

Nickel

Secondly is nickel’s effect to enhance the strength of steel while preserving decent toughness and plasticity. Nickel comes with a high corrosion resistance to alkali and acid, and is heat and rust resistant. However, due to its scarcity as a resource, it might be preferable to utilise other alloy elements.

Molybdenum

Third on the list is molybdenum, an element that ensures steel grain refinement, hardens the metal, and increases thermal ability. Molybdenum is able to maintain decent strength and creep resistance. Creep is the deformation that occurs under long-term stress at high temperatures. Introducing the element to steel can influence mechanical properties. Moreover, it is able to inhibit the brittleness that comes from quenching. If you need help from the foremost ERW steel tube supplier in the West Midlands has, let us know.

Titanium

Next, is a metal people often think of as an alternative to steel. However, titanium offers many benefits if you include it in alloys. This material is a strong deoxidiser, capable of making the interior structure denser and provides fine grain strength. Also, it reduces ageing sensitivity and cold brittleness. Furthermore, it can increase welding performance. By introducing titanium, you could prevent internal grain corrosion.

Vanadium

This is a fantastic deoxidiser for steel. Introducing 0.5% of vanadium to an alloy can refine the grain. It also enhances the toughness and strength. Carbide forming by carbon and vanadium with high pressure and temperature can improve the ability of hydrogen corrosion resistance.

Tungsten

Since tungsten’s melting point is rather high, the impact is considerable. Tungsten, alongside carbon, can form a carbide with a high wear resistance and hardness. By adding tungsten to steel, you can improve hardness and thermal strength massively.

Niobium

The effect of niobium is it’s able to refine the grain, lowering steel’s tempering brittleness and overheating sensitivity. Strength will go up too, although toughness and plasticity will decrease. Adding it to the standard low-alloy steel can augment the anti-atmospheric corrosion. The same goes for high temperature ammonia, nitrogen, and hydrogen corrosion. Even better, niobium can increase welding performance.

Copper

Finally, we have an element that can increase steel’s strength and toughness. It can do particularly well at improving anti-atmospheric corrosion performance. The downside is that during hot processing, it is easy to generate hot brittle items. Steel with more than 0.5% copper content will also result in plasticity decreasing massively. If you keep it under 0.5%, it doesn’t affect welding performance.

Shop with the top ERW steel tube supplier in the West Midlands

At Union Steel, we supply first class products to everyone that chooses us. Our merchandise includes a fantastic amount of sizes and shapes to suit any need. You can either have them delivered or you can shop directly from us.

So, if you’d like to work with the greatest ERW steel tube supplier in the West Midlands, come to us. We can even offer advice, sharing our experience of the numerous applications for the tubing.