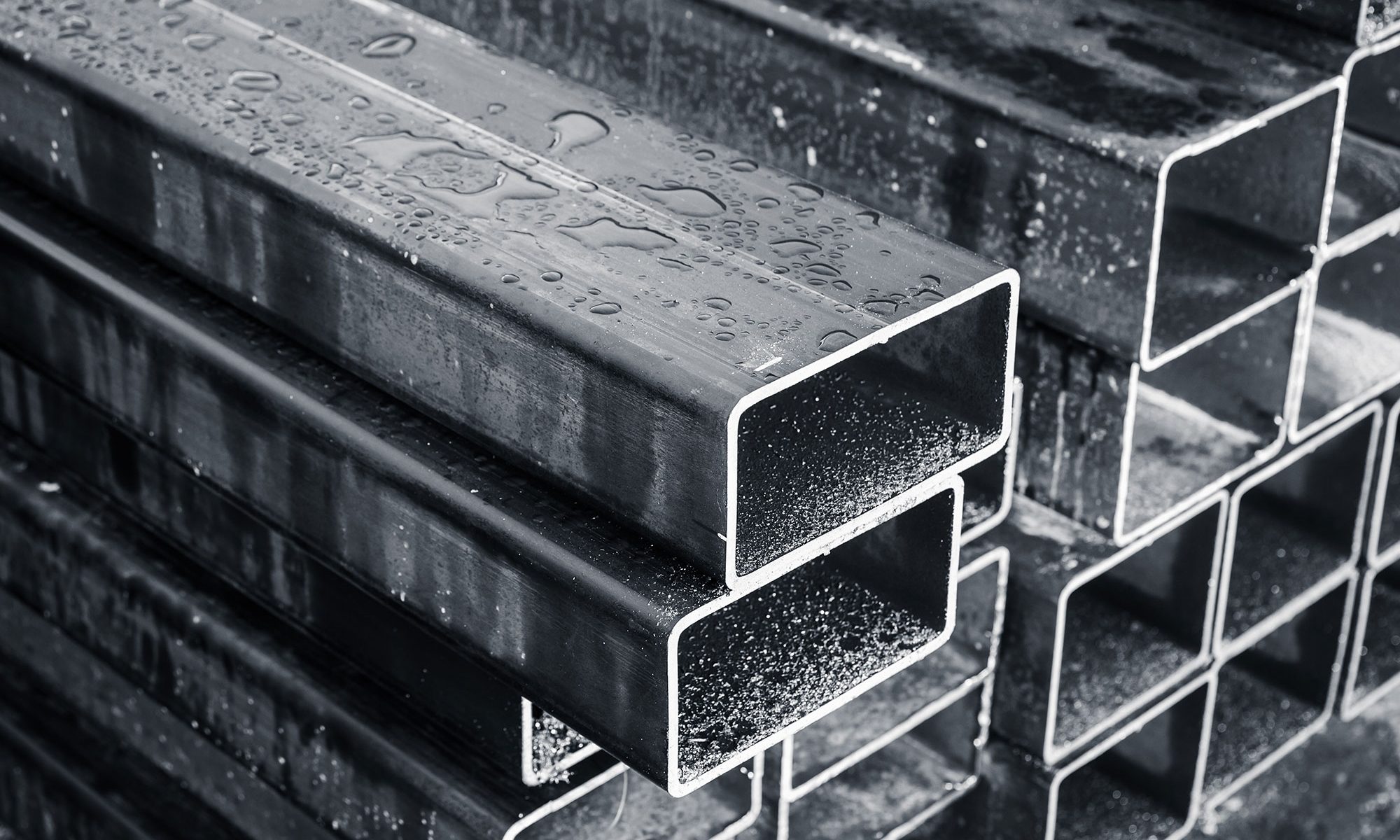

Metal tubing is fantastic for a massive array of applications. You can also choose methods to finish the tubing to suit various needs, including improving the strength and aesthetics. One option here is embossed tube. We want to have a closer look at it to see the benefits it offers. Then, if you want to order ERW tube you can speak to us.

What is it?

Most people will be familiar with the embossing technique. You can use it to create a raised design on various materials. It is a really great finishing technique that can make products far more interesting.

As you can expect, embossed tube has a pattern on the surface. It can vary massively, from simple things like lines to striations, circular patterns, wood grain, and more.

How to do it?

Embossing tube is a relatively simple process. You emboss while materials are in coil, strip, or sheet form. This makes it much easier. Typically all it takes is running the material through a rolling mill. Male/female dies press it, creating the pattern. There is high precision here and the process is easily repeatable. When you finish, you simply roll the coil, strip, or sheet to create the tubing exactly like you would with ERW tube.

Embossing tube is a relatively simple process. You emboss while materials are in coil, strip, or sheet form. This makes it much easier. Typically all it takes is running the material through a rolling mill. Male/female dies press it, creating the pattern. There is high precision here and the process is easily repeatable. When you finish, you simply roll the coil, strip, or sheet to create the tubing exactly like you would with ERW tube.

There are a number of other methods you can try if rolling is not possible. For example, machine embossing can work but has less accuracy and generally isn’t suitable for fine or complex details. Stamping, etching, laser engraving, and even water jetting can also be used. However, they have drawbacks such as costs and set up times.

Benefits

There are some notable benefits with embossed tube. For starters, it can actually increase the strength of the tubing, particularly if you use rolling to do it. The extra processing here compresses the material and helps to make it stronger. It can even work for high-strength applications.

Secondly, it can dramatically improve the aesthetics of different tubing, including ERW tube. Even simple patterns can make products more attractive to look at. However, you can be really creative here to get the look you want.

Thirdly, the embossing can improve performance in a number of ways. Because the surface is no longer smooth, it can improve things like fluid dispersion and traction. It can massively increase the surface area too, boosting heat transference.

Lots of options

You can choose embossing for various kinds of tubing, including different types of steel, aluminium, copper, brass, and more. Because you emboss the coil, strip, or sheet, you can cater for any sizes, from small diameter tubes to massive gas pipes.

Do you want to order quality ERW tubes?

Union Steel Tubes is one of the UK’s leading providers of ERW tubing. We want to ensure every single client can find what they need, so we offer a range of shapes, sizes, and finishes. On top of that, we can provide advice if clients need any, sharing our experience with different applications for the tube.

So, if you ever need ERW tube, we recommend you speak to us. We’ll do all we can to ensure you get the best products and a professional service.