There was a time when the steel industry was the most important in the world. It was vital for industrialisation and economic growth. It is still pivotal today, employing over 6 million people globally according to World Steel Association. However, it is very different to what it was in the past. A crucial thing is the wide-spread use of automatic control. We want to look closer at this today, specifically in regards to tubing. Then, if you want to order ERW steel tubes in the West Midlands, you can talk to us.

Traditional controls

One of the most notable improvements in the steel industry, particularly with tube, is the improvements in quality. You can buy products today that are vastly superior to past models. They can be stronger, more durable, have fewer flaws, and last longer. A key thing here is the development and use of computers and automatic controls.

One of the most notable improvements in the steel industry, particularly with tube, is the improvements in quality. You can buy products today that are vastly superior to past models. They can be stronger, more durable, have fewer flaws, and last longer. A key thing here is the development and use of computers and automatic controls.

In the past, it was up to people to manage all stages of steel manufacturing and processing. Even if they were using massive equipment, there would generally still be people in charge. Welding in particular was a manual task. It was up to the welders to ensure they were consistent and achieving good bonds. However, even the most skilful people could make mistakes.

Today

You are unlikely to see as many people in steel manufacturing and processing facilities today. Instead, they generally feature more modern equipment. You usually only have a few people to operate the machines and manage things.

Welding is the biggest change. You probably won’t see welders physically working to weld tube. Instead, the majority of lines are producing ERW (electric resistance welding) tubing. Here you generate heat by utilising an electric current. Pressure then squeezes the edges together to bond. The process can be automated.

The major thing here is the improvement in quality. With manual welding, the welder has to control energy output and the level of heat. If they aren’t careful, it can drop and there can be flaws in the welds. Automatic controls maintain the output and level instead of relying on a person to do it. So, it can ensure issues like cold welds and overheating don’t occur. Plus, it can keep the heat affected zone (HAC) small.

Automatic controls can also have a positive impact on several other parts of the steel industry and tube manufacturing. Crucially, computers with detection technology can more effectively spot and respond to problems. They are better for non-destructive testing, including eddy current exploration and hydraulic testing.

Overall, steel and tubing is much higher quality today because of automatic controls. That is why a lot of old pipeline infrastructure has been upgraded, replacing old spiral arc welded pipes with more durable ERW tube. Many countries now also specify that new lines can’t be made of spiral pipe; they must be appropriate ERW tubing.

Do you want to order reliable ERW steel tubes in the West Midlands?

Union Steel Tubes is very proud to use modern equipment and technology to deliver our high quality products. In fact, things like automatic controls are essential in helping us stick to ISO9001 standards. It ensures we can give our clients the best tubing.

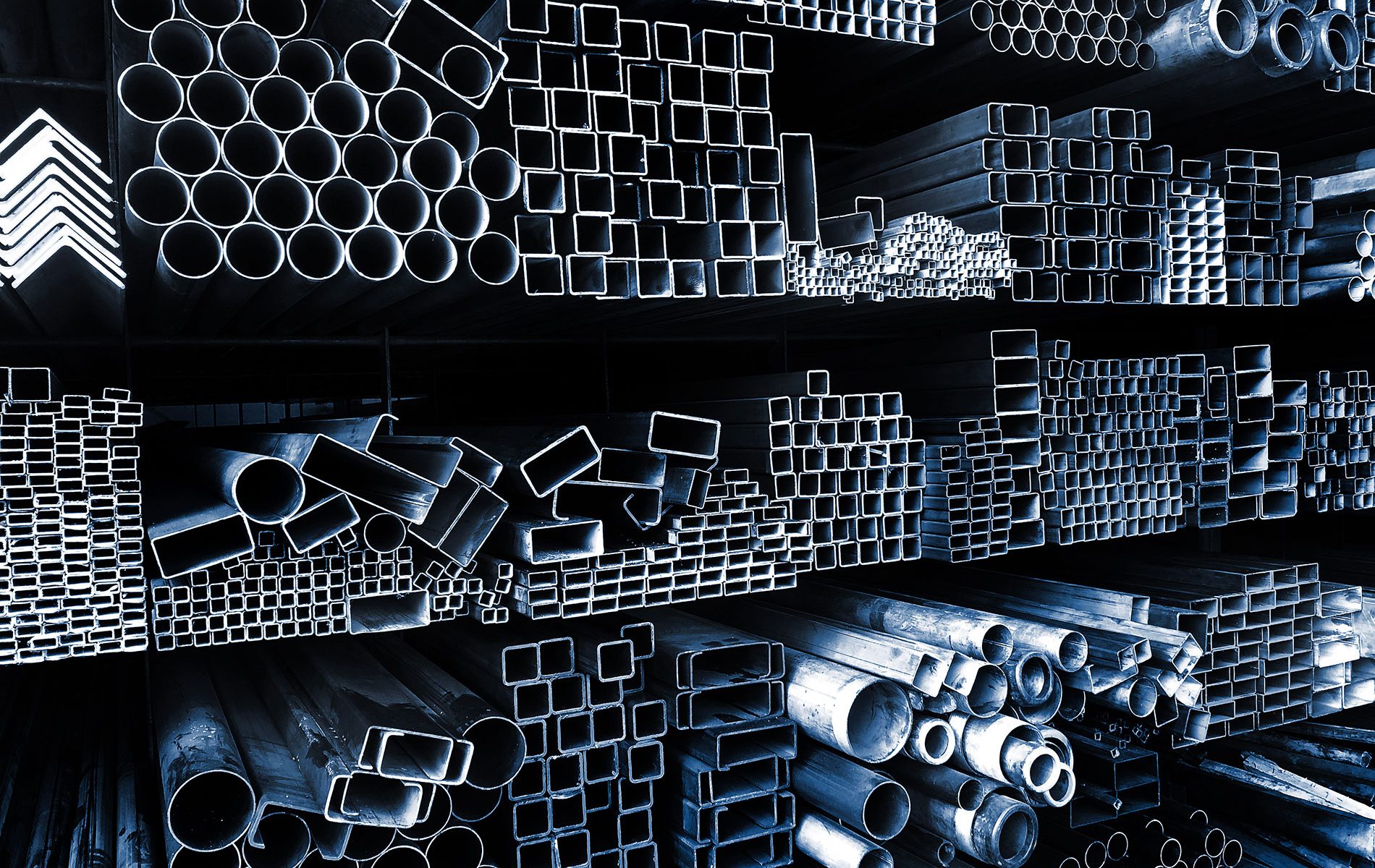

So, if you want to order ERW steel tubes in the West Midlands, speak to us. We have a range of shapes, sizes, and more. You can even ask us for advice if you are unsure of critical things like specifications.